Sona Construction Technologies Pvt Ltd

01-01-1970

The water cement ratio is one of the most fundamental and influential parameters in concrete construction. It plays a decisive role in determining the strength, durability, workability, and long-term performance of concrete. Despite being a simple concept, incorrect understanding or poor control of the water cement ratio is one of the most common reasons for weak and defective concrete structures. This blog explains the meaning of water cement ratio, why it is important, how it affects concrete properties, how to calculate water cement ratio, and how it is linked to the cement mix ratio for concrete. All related terms are explained in a clear and professional manner.

In concrete technology, the water cement ratio controls the chemical reaction between cement and water, known as hydration. This reaction is responsible for the binding and hardening of concrete. For complete hydration of cement, a minimum amount of water is required. Any water added beyond this requirement does not increase strength. Instead, excess water creates pores in the hardened concrete, reducing its strength and durability.

The importance of the water cement ratio lies in its direct impact on almost every property of concrete. A slight increase or decrease in this ratio can significantly change the performance of the concrete. A well-controlled water cement ratio ensures: Higher compressive strength Improved durability Lower permeability Better resistance to cracking Longer service life of the structure On the other hand, an uncontrolled ratio can result in weak concrete, early deterioration, and costly repairs.

Water performs two critical functions in concrete. First, it chemically reacts with cement during hydration to form binding compounds. Second, it provides workability, allowing concrete to be mixed, placed, compacted, and finished. Excess water is harmful. To avoid adding extra water during finishing, tools such as bull floats are commonly used to level and smooth fresh concrete surfaces without increasing the water cement ratio, reducing bleeding and surface weakness.

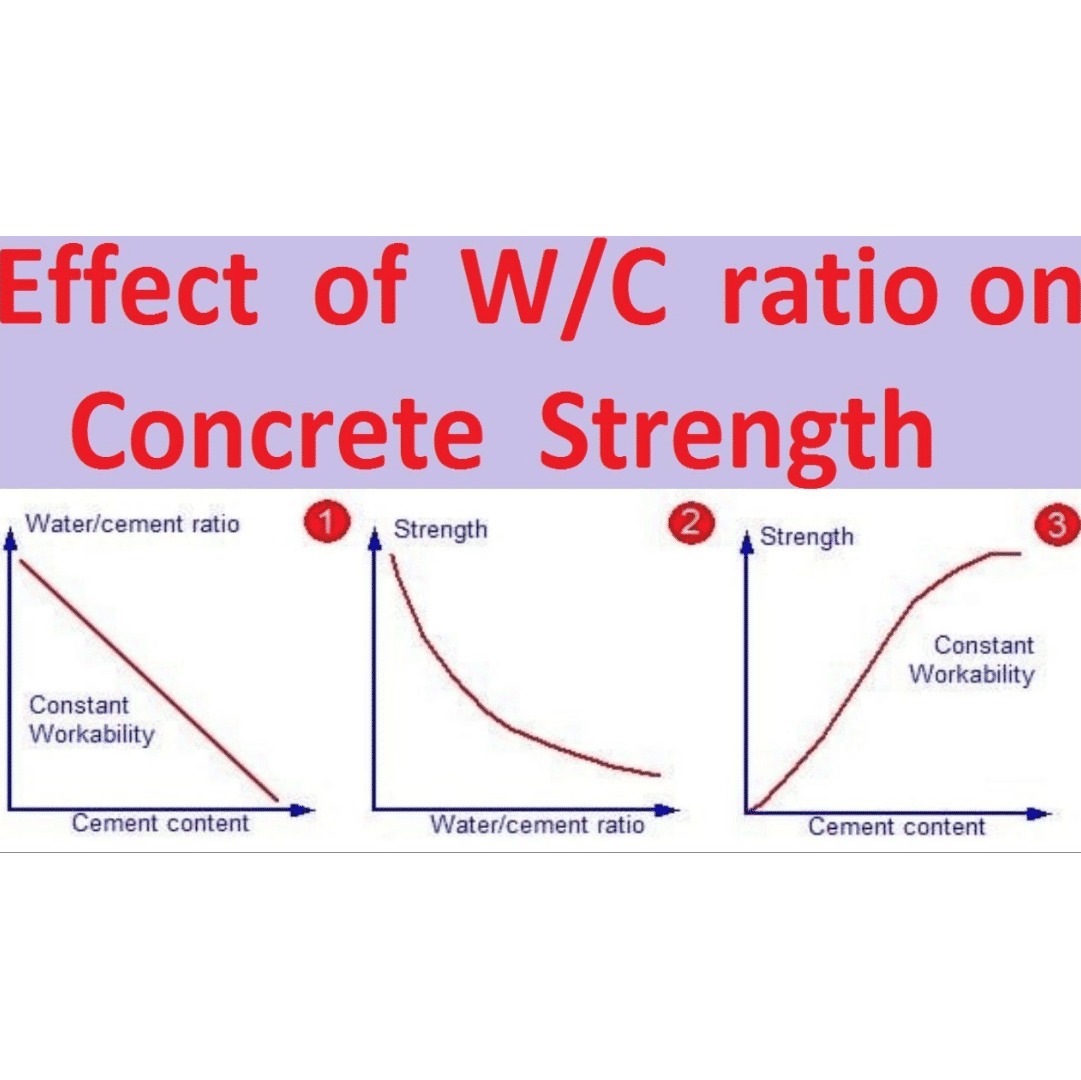

Concrete strength is inversely proportional to the water cement ratio. Lower ratios produce denser concrete with higher strength, while higher ratios create capillary voids that weaken the concrete. During slab and floor construction, power trowels are widely used to achieve dense, strong surfaces without adding water, ensuring surface strength is maintained even with low water cement ratios.

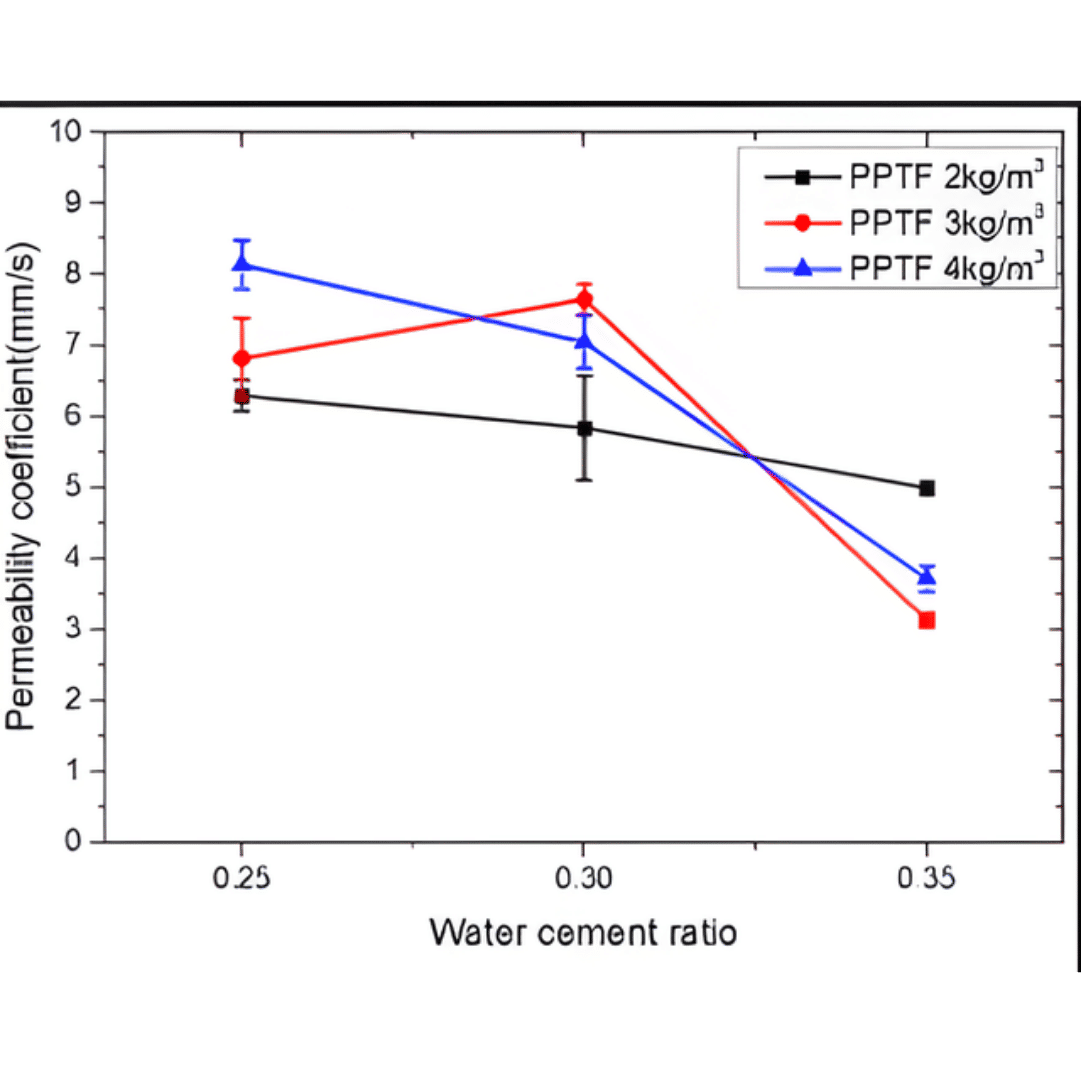

Durability depends on how easily water and chemicals penetrate concrete. Low water cement ratios produce dense concrete with reduced permeability and improved protection of reinforcement. Proper compaction plays a major role here. screed vibrators help achieve effective compaction and surface consolidation, especially when low water cement ratios are used, reducing voids and improving durability.

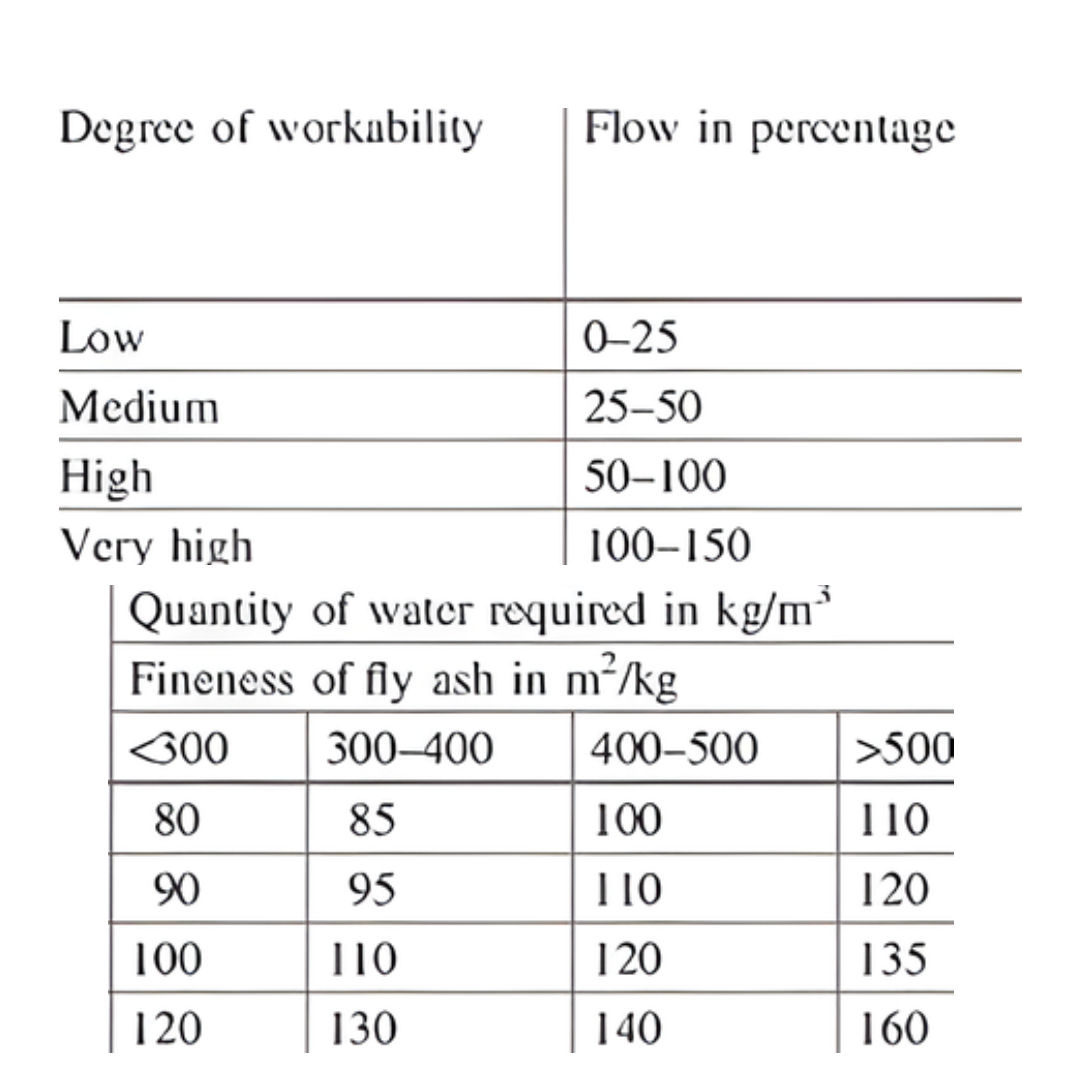

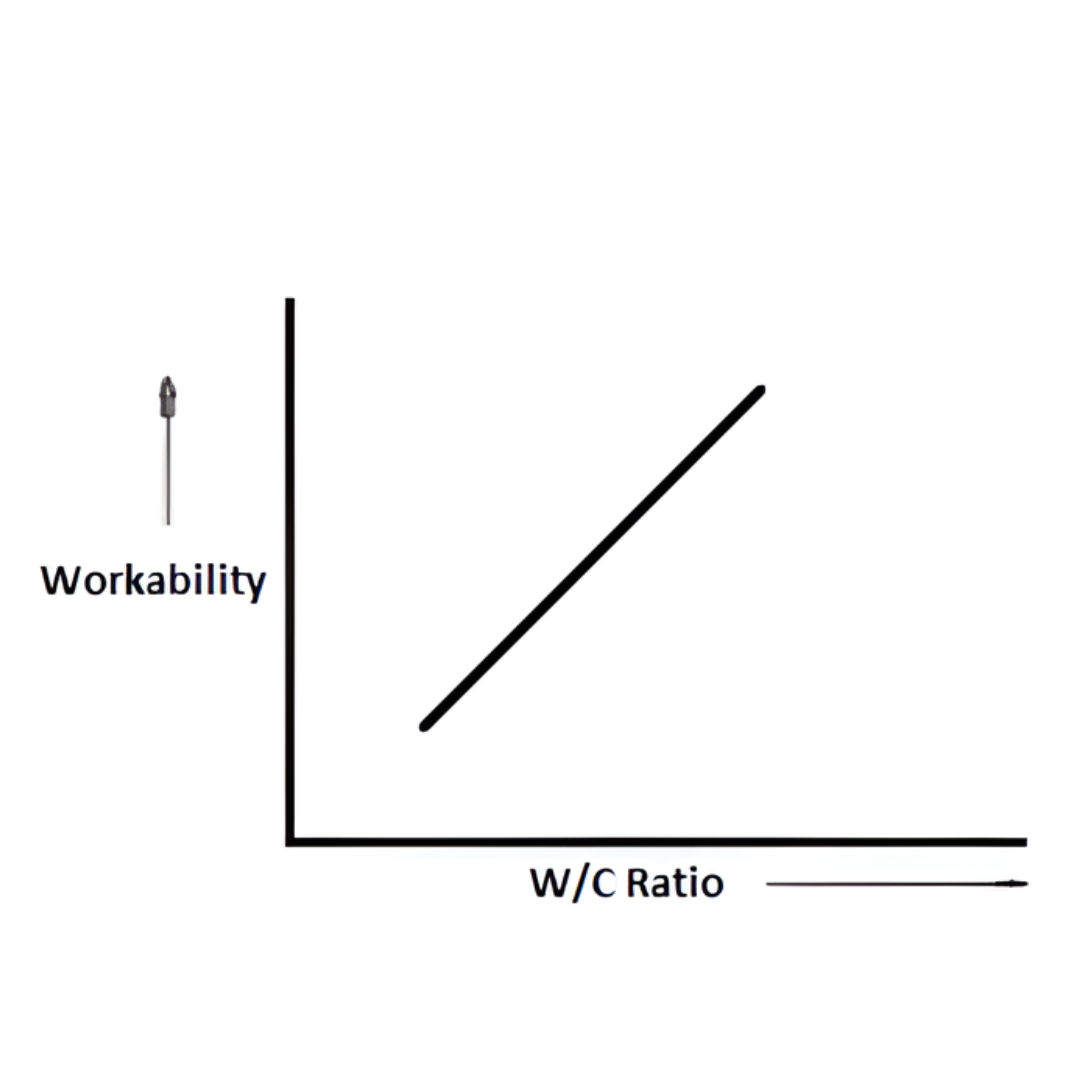

Workability defines how easily concrete can be placed and compacted without segregation. Increasing water improves workability but reduces strength. Reducing water improves strength but makes handling difficult. To overcome this, equipment such as concrete flattening machines is used to level and finish concrete efficiently without altering the water cement ratio, especially in flooring and pavement works.

Cement quantity should always be measured by weight, usually in bags (25 kg or 50 kg per bag). The total weight of cement used in a batch must be recorded before adding water. Any variation in cement quantity directly affects the calculated water cement ratio.

Water must be measured using calibrated containers or water meters. Random bucket measurement should be avoided. Since one litre of water weighs approximately one kilogram, accurate volume measurement helps in correctly calculating the water cement ratio.

Aggregates often contain surface moisture, especially sand. This moisture contributes additional water to the mix. If ignored, the actual water cement ratio becomes higher than intended. Site engineers must adjust mixing water after considering aggregate moisture.

Although the slump test does not directly measure water cement ratio, an unusually high slump often indicates excess water. Sudden changes in slump values signal poor control of water addition.

Maintaining batch-wise records of cement and water quantities is one of the most reliable ways to ensure the correct water cement ratio. Continuous supervision during mixing prevents unauthorised water addition at later stages.

A weigh batching machine measures cement, sand, aggregates, and water by weight. This ensures precise proportioning and is the most reliable method for controlling water cement ratio in large projects.

Digital scales are used to weigh cement bags, admixtures, and sometimes water containers. They provide accuracy and reduce human error compared to manual estimation.

Water measuring tanks or flow meters help ensure that only the required quantity of water is added to the concrete mix. These devices are critical for maintaining a consistent water cement ratio across batches.

The slump cone apparatus is used to check workability. While it does not calculate water cement ratio directly, abnormal slump values often indicate excess or insufficient water in the mix.

Moisture meters measure surface moisture present in sand and aggregates. This data helps adjust the mixing water and prevents accidental increase in the water cement ratio.

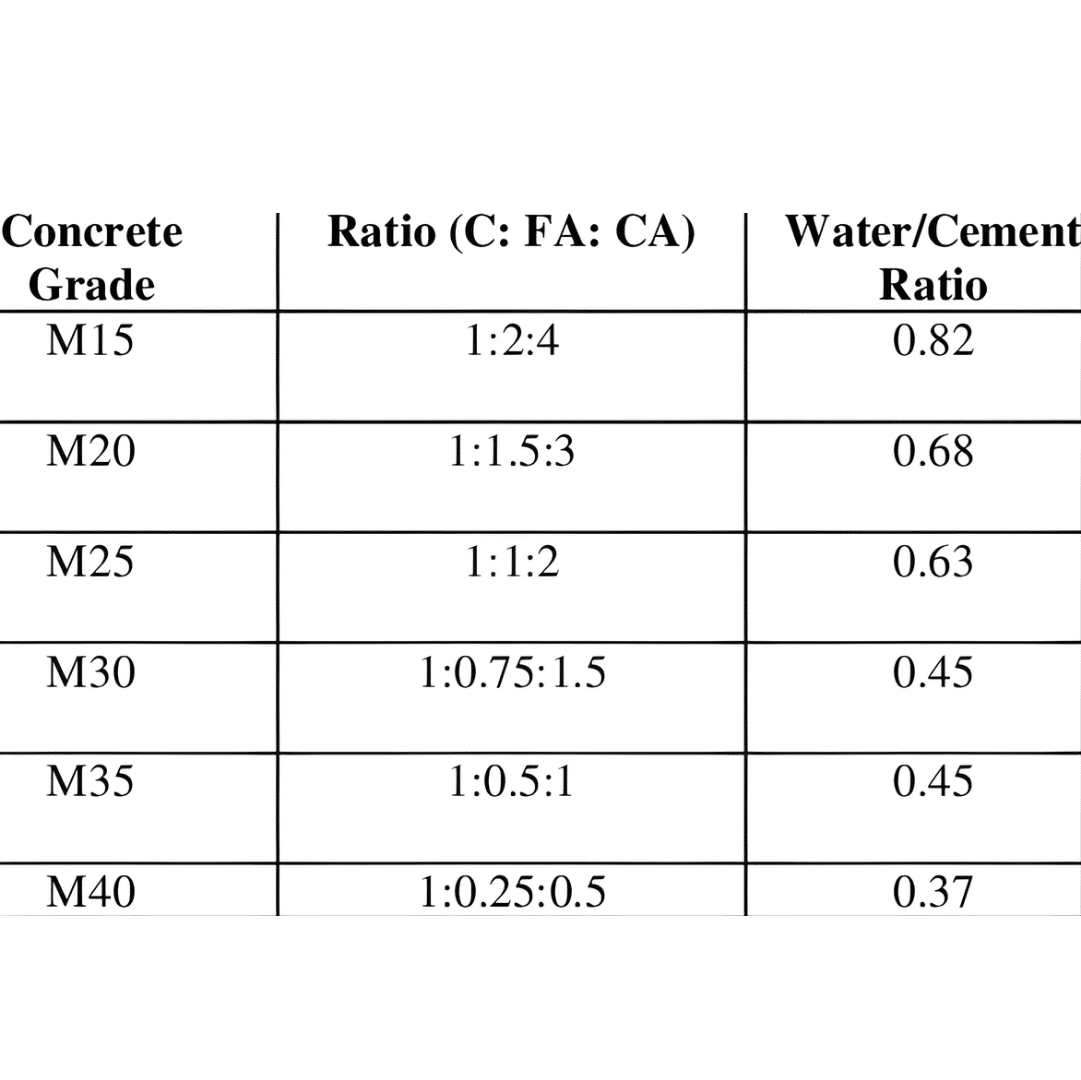

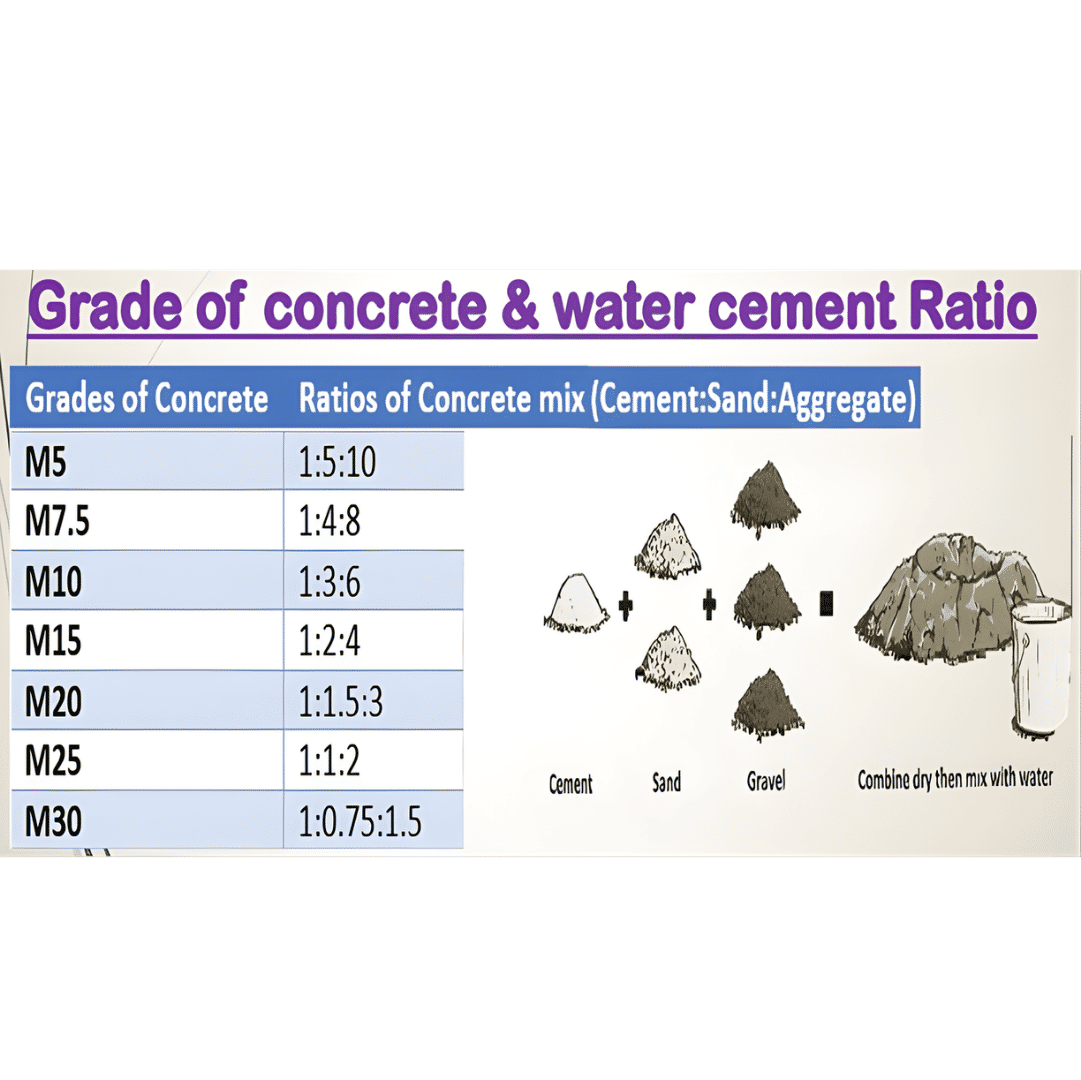

This is why modern concrete design gives greater importance to the water cement ratio than to nominal mix proportions alone.

To calculate water cement ratio, the weight of water is divided by the weight of cement used in the mix.

One of the most common site practices is adding extra water to improve workability during placing. This practice severely affects concrete quality. Other common mistakes include:

These errors lead to reduced strength, increased cracking, and poor durability.

Several construction tools directly support proper water cement ratio control:

The water cement ratio is the most decisive factor affecting the quality of concrete. While the cement mix ratio for concrete defines material proportions, it is the water cement ratio that governs strength, durability, and overall performance. Understanding how to calculate the water cement ratio and maintaining it correctly on site ensures stronger structures, reduced maintenance costs, and a longer service life. In professional construction practice, strict control of the water cement ratio is not optional—it is essential for safe and durable concrete structures.